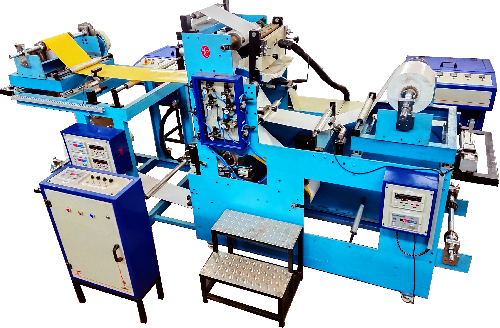

To cater the variegated demands of our precious clients, we are highly engrossed in manufacturing, supplying and trading a wide range of Hot Melt Two Side Coating Machine. This machine is a hot melt adhesive coating machine. The machine has two heads of slot die coating and two melting units. This enables coats on both sides of the substrate in a single operation. As a result, it gives double production and less wastage. This machine is designed especially for making sticky insect traps. It has the capacity to hold 300mm wide rolls and coat up to 300mm wide. Along with double coating heads, it has 3 unwinds and 1 rewind. Two unwinds hold rolls of the release liner. These liners are coated with slot dies. These slot dies are fed with molten glue by two independent melting units. Both melting units have gear pumps for the controlled, constant, and measured flow of glue. After coating on the release liners, both the papers are laminated with the PVC film sandwiched in between. This PVC film is dispensed from the third unwinder. After the lamination, all the three plies are wound at the winding station. All the unwinders are equipped with magnetic powder brakes and web guiding systems. The rewind station has a magnetic clutch for a taper tension-controlled winding.

| Adhesive GSM | 15 To 60 |

| Coating Type | Slot Die |

| Coating Width | 300 Mm |

| Country Of Origin | Made In India |

| Voltage | 415 V |

| Model Name/Number | HMC 12 2 |

| Usage/Application | Hot Melt Coating On Both Sides Of The Substrate For Making Specialty Adhesive Tapes |

| Brand | Trasy |